ADC

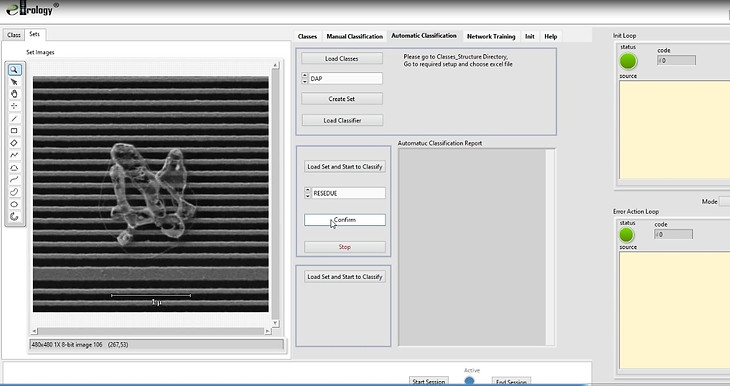

(Automated Defect Classifier)

Simple and innovative Defect Metrology Solution

ADC

ADC (Automated Defect Classifier) has The semiconductor industry increasingly relies on Automatic Defect Classifiers (ADCs) to enhance manufacturing efficiency and precision. By leveraging AI and machine learning, ADCs can rapidly identify, classify, and prioritize defects, minimizing human intervention and reducing production delays. This technology ensures higher yield and reliability in advanced chip production. As defect detection becomes more complex, ADCs play a critical role in meeting the industry's ever-growing quality standards.

ADC specifications

ADC by LVTailoring offers flexible operation modes, including Manual, Semi-Automatic, and Fully Automatic. Extensive testing demonstrates classifier performance ranging from 85% (achieved with smaller training datasets) to 98.5% on a highly structured 1.2GB dataset with six classes. In Fully Automatic mode, the average classification time is approximately 50ms. The ADC is compatible with both SEM and optical images, ensuring versatility across various inspection tasks.

Why LVTailoring?

Same Hardware

No need for new, highly-specialized, and expensive hardware

Same System

Re-invest in the power of your business with our innovative solution

New Capabilities

Control your capital costs, solve your performance issues and achieve your goals with ease

Save your capital dollars.

Allow us to unlock the full potential of your existing tools – using the same system, same hardware , and new software - for brand new capabilities.